Metal Forming & Rolling

Providing Experience For Your Metal Forming and Rolling Project

AWI’s precision metal forming and metal rolling capabilities will ensure you receive quality metal fabrications to fit your needs. With a history in fabrication dating back to 1970, AWI brings experience to your project. Our in-house Engineering team transforms your ideas into reality, while focusing on quality. AWI is ISO 9001:2015 certified. The dedicated AWI Customer Service team makes sure you get what you need when you need it. The entire team understands metal fabrication and the impact specifications and functionality have on metal forming and rolling projects.

Metal Forming Capabilities

Metal forming is the process of bending or forming steel with the use of a mechanical press brake. The steel is formed with the aid of dies to achieve precision formed parts. AWI capabilities include multiple press brakes ranging from 35 ton to 485 ton.

- – 485 Ton Press Brake – 14’

- – 230 Ton Press Brake – 14’

- – 135 Ton Press Brake – 10’

- – 60 Ton Press Brake – 6’

- – 35 Ton Press Brake – 4′

Formed Trench Drains

Electric Press Brake

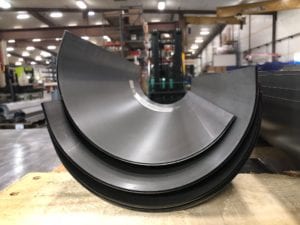

Metal Rolling Capabilities

Metal rolling is the process of passing metal through one or more pairs of rollers. This allows you to roll flat metal into a cylinder or roll a large radius onto a flat part. Things such as plow blades or tanks would be made in this matter. AWI uses three rollers ranging from 3 feet – 10 feet.

- – 10’ x 4′ Roller

- – 5’ x 3′ Roller

- – 3’ x 3′ Roller

Rolled Radius

CNC Roller

Want to discuss your project with someone from AWI?